|

|

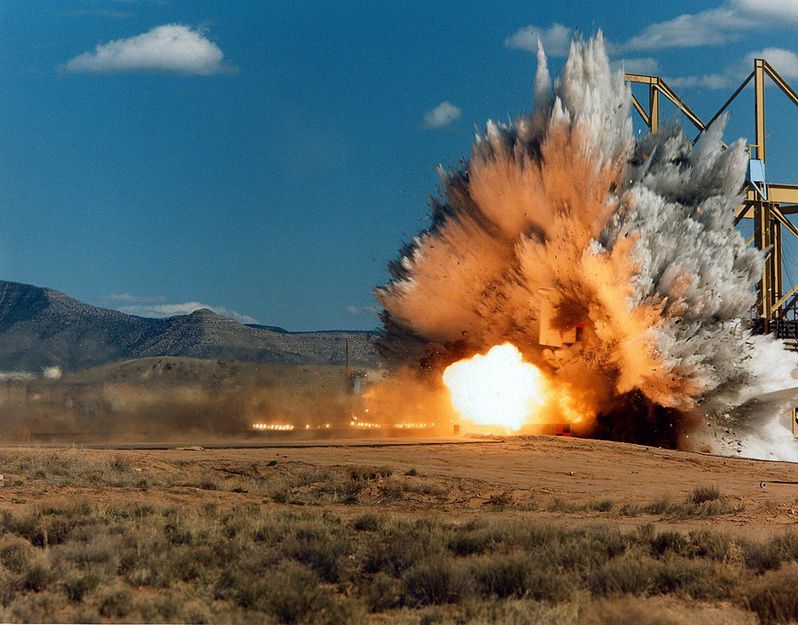

Space Shuttle Crash Test

|

Two solid rocket boosters (SRBs) each provided 12.5 million newtons (2.8 million lbf) of thrust at liftoff, which was 83% of the total thrust needed for liftoff. The SRBs were jettisoned two minutes after launch at a height of about 150,000 feet (46 km), and then deployed parachutes and landed in the ocean to be recovered. The SRB cases were made of steel about ½ inch (13 mm) thick. The Solid Rocket Boosters were re-used many times; the casing used in Ares I engine testing in 2009 consisted of motor cases that had been flown, collectively, on 48 shuttle missions, including STS-1.

• Orbiter add-ons

The orbiter could be used in conjunction with a variety of add-ons depending on the mission. This has included orbital laboratories (Spacelab, Spacehab), boosters for launching payloads farther into space (Inertial Upper Stage, Payload Assist Module), and other functions, such as provided by Extended Duration Orbiter, Multi-Purpose Logistics Modules, or Canadarm (RMS). An upper-stage called Transfer Orbit Stage (Orbital Science Corp. TOS-21) was also used once. Other types of systems and racks were part of the modular Spacelab system — pallets, igloo, IPS, etc., which also supported special missions such as SRTM.

|

|